After more than two years of investigation, field trials and internal change management processes, the world’s biggest miner, BHP has adopted Segnut in its WA Iron Ore operations. This week saw the final supply agreement being executed between BHP and Segnut Trading Pty Ltd. The agreement sets in place agreed pricing and terms of trade and registers the product on BHP’s Global Contract Management system, allocating inventory numbers against which BHP operations can order Segnut.

Segnut Goes Global: Zambia Welcomes Segnut

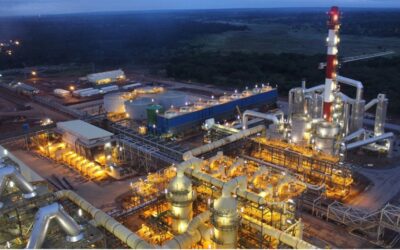

One of the biggest copper producing mines in Africa has become the second of First Quantum Minerals’ operations to adopt Segnut.

FQM adopted Engentus’s innovative Segnut in late 2018 at its Kansanshi operations and was the first mining company to adopt Segnut into its day-to-day operations. Segnut is used in the Sentinel copper mine to retain the wear liners on chutes and other fixed plant elements. Segnut has reduced the removal time and minimised the need for high energy removal methods such as hot works and rattle guns. This uniquely allows for a highly productive and lower risk work environment.

0 Comments