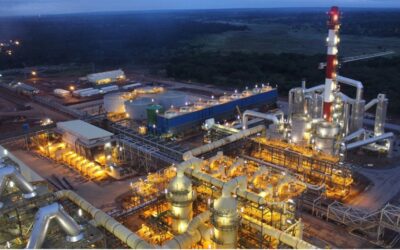

One of the biggest copper producing mines in Africa has become the second of First Quantum Minerals’ operations to adopt Segnut.

FQM adopted Engentus’s innovative Segnut in late 2018 at its Kansanshi operations and was the first mining company to adopt Segnut into its day-to-day operations. Segnut is used in the Sentinel copper mine to retain the wear liners on chutes and other fixed plant elements. Segnut has reduced the removal time and minimised the need for high energy removal methods such as hot works and rattle guns. This uniquely allows for a highly productive and lower risk work environment.

Engentus welcomes Advance Manufacturing Growth Centre

Engentus has had the benefit of outstanding support from our customer, BHP and the Advance Manufacturing Growth Centre in the development and commercialisation of it’s FIRST solution (Fully Internailised Reaction Socket Technology). Last month, our technical centre in Perth welcomed the CEO of AMGC, Jens Goenneman and its State Director for WA, Angela Doyle to demonstrate the system, which is close to final commercial release.

BHP Confirms Segnut as an Approved Product

After more than two years of investigation, field trials and internal change management processes, the world’s biggest miner, BHP has adopted Segnut in its WA Iron Ore operations. This week saw the final supply agreement being executed between BHP and Segnut Trading Pty Ltd. The agreement sets in place agreed pricing and terms of trade and registers the product on BHP’s Global Contract Management system, allocating inventory numbers against which BHP operations can order Segnut.

Maintenance Productivity & Safety Gains – Successful Trials at Rio Tinto

After nearly two years of close cooperation including technical trials, laboratory tests and rigorous field trials, Segnut has been officially accepted by BHP for use in its WA Iron Ore operations. In 2017, the screen house at Mount Whaleback mine caught fire as a result of hotworks being used to remove a seized nut. In Segnut, BHP found a means of removing the need for hot works to remove seized fasteners, that requires no special tools, nor changes to the design of the chutes, wear liners or other equipment. By replacing common hex nuts on wear liners and hard skirts on conveyors, BHP aims to remove the risk of a hot works (spark–ignited) fire in areas of high fuel load, such a screen houses and car dumpers.

Queensland Mining Expo

Queensland Mining ExpoAug 20, 2019 Konnecting with Queensland mining delegates!Segnut was proud to exhibit with our exclusive Australian and New Zealand Distribution partner, Konnect Fastening Systems at the Queensland Mining Expo in Mackay, QLD.

Segnut addresses MESCA event in Perth

Segnut addresses MESCA event in PerthAug 29, 2019 Segnut’s Director – Product Development, Tom P. Baskovich, addressed delegates at a Mining and Energy Services Council of Australia (MESCA) briefing in Perth on Wednesday 28 August.

Segnut featured in Australian Mining magazine

Segnut featured in Australian Mining magazineSept 19, 2019 Australia Mining Magazine reports on Segnut innovation, and reducing maintenance costs. Mining maintenance spending in Australia is expected to rise by more than 60 per cent annually to $12 billion by 2022